Why Choose Professional Welding Inspection Madison for Your Projects

Recognizing the Basics of Welding Assessment to Ensure High Quality and Safety And Security

In the realm of modern design, welding inspection stands as a keystone for making sure both the quality and security of structural creations. The procedure entails a thorough evaluation of welded joints, using innovative methods such as ultrasonic and radiographic testing to spot covert flaws. The knowledge of certified examiners is important, as they connect the gap in between theoretical requirements and sensible application. Their duty extends beyond simple discovery, incorporating the documentation and communication of findings to pertinent stakeholders. Yet, what are the subtleties of these examination methods that make them indispensable for preserving structural stability?

Value of Welding Inspection

In the world of industrial fabrication, the value of welding examination can not be overstated. Welding examination plays a crucial duty in guaranteeing the integrity, security, and longevity of bonded structures (Welding Inspection Madison).

The process of welding inherently includes complex variables, consisting of temperature, product homes, and environmental problems, all of which can influence the high quality of the weld. A thorough inspection recognizes problems such as splits, porosity, and incomplete fusion, which can endanger the toughness and dependability of the weld. By identifying these problems early, restorative activities can be taken, therefore decreasing the threat of failing and linked expenses.

Furthermore, welding examination adds to governing compliance, as several markets are controlled by stringent security standards and standards. Failure to follow these guidelines can result in lawful liabilities and financial penalties. Eventually, welding examination not only safeguards physical structures but additionally upholds and protects human lives market online reputations.

Secret Welding Evaluation Techniques

Although welding evaluation is critical to guaranteeing the top quality and safety of bonded structures, it is the details approaches utilized that determine the performance of the examination procedure. Secret welding evaluation techniques can be broadly categorized right into non-destructive screening (NDT) and devastating testing. Non-destructive screening approaches such as aesthetic examination, ultrasonic screening, radiographic testing, magnetic bit screening, and liquid penetrant screening are mainly utilized to assess the residential or commercial properties of a weld without triggering damages. Visual evaluation is frequently the first step, entailing a complete examination of the weld's surface area for problems like splits or porosity.

Magnetic fragment screening and liquid penetrant screening are surface area evaluation techniques made use of to locate surface and near-surface problems. These comprehensive inspection techniques make sure that welds fulfill industry requirements and safety and security needs, thus ensuring structural stability and performance.

Function of Qualified Inspectors

Certified examiners play a crucial role in the welding inspection process, making certain that all welds follow strict industry requirements and security policies. Their know-how is necessary in identifying flaws or irregularities that may jeopardize the structural honesty of a weld. By thoroughly analyzing each weld, accredited inspectors help stop possible failures that could cause costly fixings or hazardous accidents.

To become qualified, assessors must undergo rigorous training and testing, which familiarizes them with various welding techniques, materials, and screening techniques. This thorough expertise permits them to assess weld high quality successfully and make informed judgments regarding their safety and security and reliability. Moreover, certified inspectors excel in analyzing specifications and blueprints, ensuring that the welding job aligns with the job's style requirements.

An important part of their role is to record their findings extensively, supplying a comprehensive record of the evaluation process. Their payment is indispensable in preserving high degrees of quality and security in welding procedures.

Devices Made Use Of in Welding Inspection

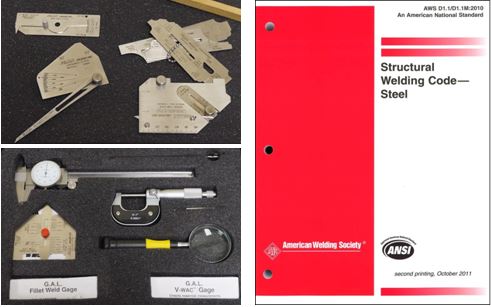

Welding examiners count on a selection of specialized tools to perform their tasks properly, making sure each weld satisfies the required requirements. Among these tools, visual assessment help like amplifying glasses and mirrors are fundamental, allowing examiners to very closely check out welds for surface area flaws such as cracks, porosity, and undercut. Calipers and fillet weld gauges are crucial for measuring weld dimensions to validate conformity with style requirements.

Advanced devices expand beyond aesthetic aids, including non-destructive screening (NDT) devices. Ultrasonic testing tools are pivotal in detecting subsurface imperfections, utilizing acoustic waves to reveal interior gaps without jeopardizing the weld's stability. Radiographic screening uses X-rays or gamma rays to record photos of a weld's inside, highlighting prospective problems.

Magnetic fragment website here screening is one more essential device, particularly for spotting surface area and near-surface discontinuities in ferromagnetic materials. By applying ferrous particles and magnetic fields, inspectors can recognize problems that might or else be unnoticeable.

Dye penetrant inspection is usually utilized for non-ferrous materials, giving a contrast-enhanced aesthetic check for surface-breaking flaws. Welding Inspection Madison. Together, these tools allow welding assessors to comprehensively assess weld top quality, making sure safety and reliability in numerous applications throughout industries

Ensuring Architectural Honesty

Welding procedures must follow established criteria and codes, such as those specified by the American Welding Society (AWS) or the International Company for Standardization (ISO) These guidelines guarantee that the welds can withstand ecological elements and operational stress and anxieties. Qualified and certified welders play a critical function in this process, as their experience makes certain that techniques are applied appropriately, lessening problems such as cracks, porosity, and insufficient fusion.

Post-weld examination is one more essential part of confirming architectural integrity. These examinations confirm that the welds meet the called for high quality criteria, giving assurance of their durability and reliability.

Conclusion

The basics of welding examination are crucial for keeping the high quality and safety of bonded frameworks. By applying crucial examination techniques, such as aesthetic evaluations and non-destructive testing, potential problems that could endanger structural stability are recognized. Certified examiners are crucial in making sure conformity with industry requirements and reliable interaction amongst stakeholders. The usage of specialized tools additionally enhances the inspection process, ultimately safeguarding human lives and prolonging the lifespan of welded constructions.

Welding examination plays an important duty in making click to investigate sure the integrity, security, and long life of bonded frameworks.Although welding examination is vital to ensuring the top quality and safety of welded structures, it is my link the specific approaches employed that determine the efficiency of the evaluation procedure. Trick welding examination approaches can be broadly classified into non-destructive testing (NDT) and devastating screening.Qualified assessors play a pivotal role in the welding inspection procedure, making certain that all welds comply with rigorous industry requirements and security laws.The principles of welding assessment are essential for keeping the quality and safety of bonded frameworks.